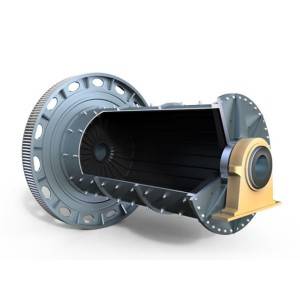

Rubber mill liners

Cov roj hmab liner maj mam hloov cov manganese steel liner. Nws tuaj yeem dais muaj zog cuam tshuam ntawm kev ua haujlwm. Cov txiaj ntsig ntawm koj cov sib tsoo circuits yog nyob ntawm koj lub zeb cov roj hmab liner. Xaiv txoj cai ntawm koj tus neeg muag khoom roj hmab ua tib zoo yuav ua kom koj cov txheej txheem milling khiav ntawm lub peev xwm siab tshaj plaws thiab muaj.

Cov roj hmab liners feem ntau yog tsim rau kev sib tsoo ntub dej, qhov kub tsis siab tshaj 80 degrees ntawm kev ua haujlwm ib txwm muaj, tab sis rau qhov kub thiab txias sib tsoo, muaj zog acid thiab alkali tsis kam, roj kuj thiab lwm yam tshwj xeeb ib puag ncig, yuav tsum tau piav qhia ua ntej los ntawm kev sib cais. tsim qauv thiab kev cai ua, ntxiv rau, cov txheej txheem cia yuav tsum tau muab tso rau hauv kev saib xyuas hauv tsev kom zoo, nws npaj cov roj hmab liners los tiv thaiv sab nraum zoov hauv qab kub thiab los nag.

Raws li lub hom phiaj, cov roj hmab liner tau muab faib ua: AG, SAG, pob, pebble, pas nrig & batch mills, FGD, SMD thiab nruam mills.

Raws li cov duab, nws tau muab faib ua ntau hom, kab sib chaws thiab ntau hom, uas tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm ib-theem ntxhib sib tsoo thiab ob-theem zoo sib tsoo.

Peb tuaj yeem hloov kho txhua yam ntawm cov khoom zoo thiab siab hnav-resistant roj hmab liners raws li qhov xav tau ntawm txhua tus neeg siv khoom.

Nta

1. Tsawg zog noj

2. Siab hnav tsis kam

3. Kev saib xyuas tsawg

4. Kev cuam tshuam tsis kam

5. Tsawg suab nrov

6. Yooj yim rau nruab

7. Corrosion resistant

8. Txuag cov pob steel

① Lifter Bars

Lifter Bars muaj nyob rau hauv ntau qhov dav, qhov siab thiab roj hmab lossis cov ntaub ntawv sib xyaw. Lifter Bars suav nrog cov hlau ntxig yog tsim los muab kev cuam tshuam ntau tshaj plaws thiab ua kom puas.

② Filling & Corner Segments

Filling thiab Corner Segments yog tsim los xauv lub taub hau daim hlau thiab Grate Phaj rau hauv txoj hauj lwm thiab nres cov khoom sib tw ntawm cov ces kaum.

③ Lub taub hau daim hlau

Roj Hmab Daim Hlau muaj nyob rau hauv ntau yam tsim los tiv thaiv zawv zawg abrasion. Lub taub hau phaj yog tsim los pab kom yooj yim ntawm installation thiab tuav

④ Grate Phaj

Heavy-lub luag hauj lwm Grate phaj tsim muaj rau cov mills loj. Cov cuab yeej elastic ntawm cov roj hmab tso cai rau cov qhov me me dua li cov hlau grate thaum tshem tawm cov teeb meem dig muag. Muaj nyob rau hauv ntau qhov ntau thiab tsawg aperture.

⑤ Center Cones & Trunnion & Tswb Qhov ncauj Liners

Center Cones tuaj yeem tsim hauv ntu kom yooj yim ntawm kev teeb tsa.

Trunnion & Tswb Qhov ncauj Liners

Trunnion Liners yog tsim los ntawm cov khoom siv hlau, uas yog cov roj hmab lined. Loose steel-backed roj hmab liners kuj siv nyob rau hauv loj Trunnion thiab Tswb Qhov ncauj linings.

⑥ Outer Pulp Lifters

⑦ Sab hauv Pulp Lifters

Roj Hmab Lined Pulp Lifters yog tsim los muab qhov tseeb tso tawm ntawm cov ntaub so ntswg los ntawm lub zeb kom txo tau lub raj mis-caj dab.

⑧ Plhaub daim hlau

Lub thickness ntawm lub plhaub phaj tuaj yeem sib txawv txhawm rau txhawm rau nce lub peev xwm zeb thiab / lossis lub neej liner. Qhov dav yog tsim los rau kev tiv thaiv zoo los ntawm lifter tuav.

Physical Properties Index

| Kev ua tau zoo | Chav tsev | Index |

| Lub zog tawg | MPa ≥ | 18 |

| Elongation thaum so | % ≥ | 420 |

| 300% kev ntxhov siab tas li | MPa ≥ | 12 |

| Hardness | Ntug A (degree) | 64-68 : kuv |

| Akron puas | cm³/1.61km | 0.1 |

| Kev cuam tshuam elasticity | % ≥ | 45 |

| Tearing mus tas li deformation | % ≥ | 10 |

| Adhesion ntawm roj hmab thiab hlau | KN / m | 6 |

Tag nrho cov hnub yog nyob rau hauv tus txheej txheem ib txwm thiab sab laj Hoobkas kom tau txais qhov tshwj xeeb customization.