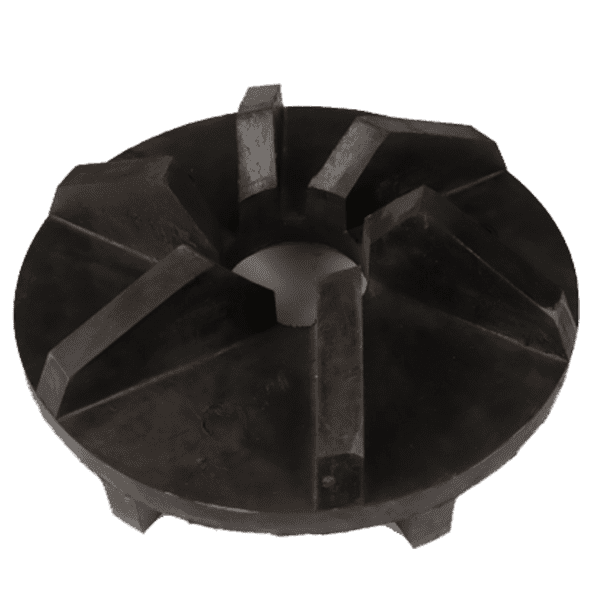

Cov roj hmab stator thiab rotor ntawm flotation tshuab

Lub stator thiab rotor, tsuas yog siv rau hauv flotation tshuab ntawm xjk series, sf series, xcf series, jJF series, BS-K series.

Lub stator thiab rotor, tsuas yog siv rau hauv flotation tshuab ntawm xjk series, sf series, xcf series, jJF series, BS-K series.

Lub rotor thiab stator ntawm cov flotation tshuab feem ntau yog tsim los ntawm cov hlau pob txha ntxig thiab hnav-resistant roj hmab. Hlau pob txha ntxig yog ua los ntawm cov nplaim hluav taws xob ua thiab tom qab ntawd welded kom raug raws li cov txheej txheem nruj me ntsis. Lub zog thiab sib npaug ua tau ntawm pob txha pob txha pob txha pob txha pob txha pob txha yog lav los ntawm ntsuas kom pom kev paub los ntawm kev siv balancer. Cov roj hmab rotor thiab stator ntawm frolotation tshuab nto tau sib khi nrog cov roj hmab resistant thiab tom qab ntawd vulcanized ntawm qhov kub.

Peb lub tuam txhab muaj 3600 tons ntawm super loj loj tiaj tus phaj vulcanizer thiab muaj lub peev xwm los tsim lub rotor thiab stator ntawm flotation tshuab los ntawm lub cheeb | mus rau 2400 hli. Yog tias qhov kev thov tshwj xeeb tshaj plaws, peb tuaj yeem hloov kho nws raws li cov neeg siv khoom.

Cov Khoom Siv Roj Hmab

| Yam | Ib yam | Phiaj qhia ntawv |

| Lub zog tensile ≥ | 17 | |

| Acid (hauv paus) coefficient 20% horso₄ (20% naoh) 18 ℃ x24h | 0.8 | |

| Elongation thaum so ≥ | % | 450 |

| Kev nyuaj | Ntug dej Hardness A | 55 ± 5 |

| Cov Cua Cua Cov Khoom Kub Laus Kev Lom Zem Rece90 ℃ X24H | 0.75 | |

| Puas Txhob Tsis Muaj | cmy / 1.61km | 0.7 |

| Cov Hlau Thiab Cov Ntoo Adhesion Yog | MPa | 2.5 |

| Kua muag puas muaj decormation nyob ib txhis | % | 30 |

| Roj Coefficient 20 # Roj 100 ℃ X24H | % | ± 10 ~ 5 |

Nta

1. Ua txhaum tsis taus

2. Kua muag Resistance

3. Cov Cuam Tshuam Kuj

4. Tshuaj Ntsuam Xyuas Kev Ruaj Ntseg

5. Lub neej pabcuam ntev

Hnav Cov Tshuaj

1.Detecting cov qauv coj thiab tus nqi nyob hauv thaj chaw tseem ceeb thiab txhawb tus yam ntxwv ntawm cov txheej txheem ua haujlwm.

2.by siv ntau cov roj hmab lossis polyurethane khoom rau qhov chaw uas xav tau feem ntau ntawm tag nrho ib feem. Thiab qhov no yuav elongate lub neej rau kev ua haujlwm.

3. Cov neeg soj ntsuam kev tshaj lij thiab kev txij nkawm thaum siv nws cov neeg siv khoom. Thiab tau txais cov ntawv qhia hloov tshiab tsis tu ncua hauv cov txheej txheem ua haujlwm, uas yuav muab thiab nce cov nroj tsuag muaj.

Hlau pob txha

1.Qhov cov khoom siv raw yog siv PCCR12 stainless hlau bosses, nyob rau hauv cov muaj xeb thiab bolt hauv kev xauv.

2.Welding txheej txheem teb ntawm ISO cov qauv los ntawm kev paub ua neeg ua haujlwm thiab khaws cov nyiaj tshuav thiab muaj tseeb thaum grooving.

3.Cov kev ua haujlwm yog nyob ntawm cov neeg yuav tsum tau ua lossis nrhiav kev daws teeb meem los ntawm peb pawg thev naus laus zis.