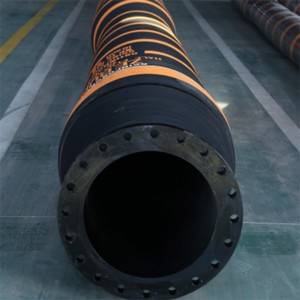

Cov Roj Hmab Lined Hlau Kav

Cov roj hmab lev dej khib nyiab yog tsim tsim los siv rau hauv cov ntawv thov nqus tawm cov abrasive. Cov ntawv thov xws li zeb tshem tawm, kev kub siab lub twj tso kua mis, cov kab ntev ntev, xav tau cov ntaub ntawv tso kua mis thiab cov kav dej khov. Txhua kawg nrog cov roj hmab vulcanized tshuab tsau flange.

Hnav-resistant thiab corrosion-resistant roj hmab kab yeeb nkab cov yeeb nkab uas yog ua los ntawm cov khoom siv steel ua haujlwm thiab siv nrog cov roj hmab-resistant thiab tshav kub-resistant thiab tshav kub-resistant thiab cov roj cua sov. Nws yog compounded los ntawm cov thev naus laus zis tshwj xeeb nrog cov nplaum ua kom zoo. Mas siv rau hauv metallurgy, hluav taws xob hluav taws xob, kev lag luam tshuaj, roj av, thee, xis mas thiab lwm yam kev lag luam. Hauv kev ua haujlwm mining, nws yog dav siv nyob rau hauv cov miv pob ntawm cov mine tailings conveying system, thee backfilling thiab lwm yam yeeb nkab teb. Tshwj xeeb, cov raj dej yog haum rau kev xa cov kub ntawm -50 ° C txog + 150 ° C nruab nrab, uas yog yooj yim hnav thiab corrosion. Peb tuaj yeem nce cov phab ntsa tuab ntawm cov yeeb nkab ces kaum raws li cov neeg siv khoom siv, yog li txuas cov kev pabcuam lub neej. Lub caij no, kev pabcuam lub neej ntawm cov roj hmab-lined steel yeeb nkab tuaj yeem ncav tau 15-40 xyoo feem ntau. Cov yeeb nkab tuaj yeem tig tau ze li 90 degrees tom qab 6-8 xyoo ntawm kev pabcuam. Txhua lub sijhawm ntawm kev sib hloov tuaj yeem txuas lub neej ua haujlwm, cov yeeb nkab steel tuaj yeem rov qab nrog cov roj hmab rau peb mus rau plaub zaug, yog li nws txo cov nqi hauv ntxiv.

Qhov ntawm cov khoom siv tshwj xeeb rau cov roj hmab-kab yeeb nkab

| OD / hli | Yeeb Nkab Phab Ntsa Thickness / hli | Ua haujlwm siab / Mpa |

| 450 | 10 ~ 50 | 0 ~ 25.0 |

| 480 | 10 ~ 70 | 0 ~ 32.0 |

| 510 | 10 ~ 45 | 0 ~ 20.0 |

| 530 | 10 ~ 50 | 0 ~ 22.0 |

| 550 | 10 ~ 50 | 0 ~ 20.0 |

| 560 | 10 ~ 50 | 0 ~ 21.0 |

| 610 | 10 ~ 55 | 0 ~ 20.0 |

| 630 | 10 ~ 50 | 0 ~ 18.0 |

| 720 | 10 ~ 60 | 0 ~ 19.0 |

Lub cev cov khoom ntawm cov roj hmab-kab yeeb nkab

| Yam | Lub hom phiaj |

| Thickness ntawm ob sab phlu (MPa) ≥ | 16.5 |

| Cov kab ntawv thiab lub cev pob txha 180 ° tev zog (kn / m) ≥ | 8 |

| Elongation ntawm cov kab (%) ≥ | 550 |

| Cov kab ntawm cov ob sab phlu tau ncab (300%, mpa) ≥ | 4 |

| Cov txheej hauv kab mob siab rau kev ua txhaum kev puas tsuaj poob qis (cm³ / 1.61km) ≤ | 0.1 |

| Hauv ob sab phlu hardness (sauer yam a) | 60 5 ± 5 |

| Tus nqi ntawm kev hloov ntawm kev siv ntawm lub thermal kev laus ntawm cov ob sab phlu (70 ℃ X 72 h,%) ≤ | 10 |

Nta

1. Kev tsim kho zoo heev

2. Cov hnav zoo tsis kam thiab ntev kev pabcuam lub neej

3. Lub zog siab thiab kev tsis kam

4. Zoo corrosion tsis kam

5. Ntau qhov ntsuas kub

6. Kev sib txuas nrawm thiab kev teeb tsa yooj yim